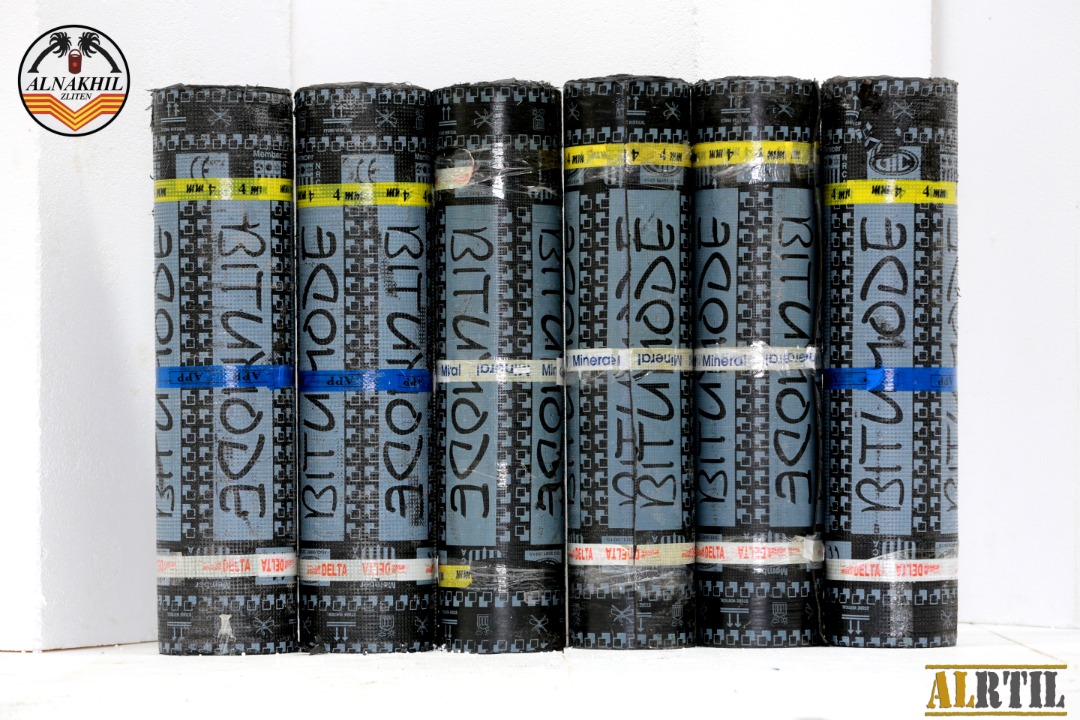

HOME | BITUMODE DELTA – P

APP MODIFIED BITUMEN PLASTOMERIC WATERPROOFING MEMBRANE

REINFORCED WITH SPUNBOND NON WOVEN POLYESTER

What is Bitumode?

Produced by the Modern Waterproofing Company, Bitumode is a line of polymer-modified bitumen waterproofing membrane of the highest quality. Bitumode is modified by APP and APAO, thus guaranteeing superior performance under various conditions.

Delta-B bitumen is a general purpose membrane, which can be applied virtually anywhere where flame modified bitumen films are specified with light exposed to moderate mechanical stresses, and normal performance at low temperatures is required.

The Delta-B bitumen can be applied to:

Single layer roofing system for normal use.

Double layer roofing system combined with fiberglass reinforced delta granulated bitumen.

Waterproofing of toilets and wet areas inside buildings.

Slab seams.

The Delta-B bitumen is recommended with a convex metal roof for exposed (unprotected) roofs or surfaces that are inaccessible and subject to low-traffic conditions

Uses BITUMODE DELTA-P is a general purpose membrane, can be applied virtually anywhere where torch applied modified bitumen membranes subject to light to moderate mechanical stresses are specified, and normal low temperature performance is required.

BITUMODE DELTA-P can be applied in:

- Single layer roofing system for normal use.

- Double layer roofing system combined with BITUMODE DELTA-G fiberglass reinforced.

- Waterproofing of toilets & wet area insidebuildings.

- Slab on grade.

BITUMODE DELTA-P with Mineral Slated Finish is recommended for exposed roofing system (Unprotected) for Non-accessible roofs or roofs subject to low traffic conditions.

Advantages BITUMODE DELTA – P has been designed with special regard to providing clients with an excellent and versatile product line. Advantages of Bitumode DELTA-P include:

- Easy to apply (by torch).

- High mechanical properties.

- Absolute impermeability to water pressure.

- Flexibility at low temperature up to -2co.

- Excellent high temperature performance.

- Excellent adhesion on any surface.

- High dimensional stability.

- Environmentally friendly.

Quality Control The Modern Waterproofing Company is ISO 9001 certified. It applies a stringent quality control system utilizing its in-house laboratory. Occasional samples are analyzed by independent laboratories to ensure continued adherence to the highest standards (ASTM, EN, etc.). Each roll of Bitumode is individually coded with a label containing all necessary information about the roll, this is intended to ensure traceability in accordance with ISO control standards.

Product Range Standard thickness available includes 3mm and 4mm. Some types could be available by weight 3kg/m2 and 4kg/m2. Bottom surface finish is normally Polyethylene Film (PE) Upper surface finish choices include:

- Polyethylene Film (PE)

- • Fine Sand (S)

- • Mineral Slated Grey (GY)

- • Mineral Slated Green (GRN)

- • Mineral Slated White (WT)

- • Mineral Slated Red (RD)

Slated rolls are available in 4kg, 4.5kg and 5kg per square meter.

The nominal length of each roll is 10 meters and the nominal width is one meter.

Special specification can be designed based on client’s needs.

| TECHNICAL DATA | TEST METHOD | UNIT | RESULT | Tolerance |

| Rool length | EN 1848-1 | m | 10 | -+ 1% |

| Rool Width | EN 1848-1 | m | 1 | -+ 1% |

| Thickness for PE finish | EN 1849-1 | mm | 2.3.4.5 | -+ 5% |

| Weight for slated surface finish | EN 1849-1 | kg/m2 | 4.4.5.5 | -+ 10% |

| Softening Point (Ring & Ball) | ASTM D-36 | °C | ||

| Penetration at 25 °c 60 °c | ASTM D-5 | dmm dmm | 15 to 25 60 to 80 | |

| Cold Flexibility | EN 1109 | °C | 0 to -2 | |

| Heat Resistance | EN 1110 | °C | 120 | |

| Reinforcement |

Non-Wowen Polyester

|

|||

| Tensile strength Long Wide | EN12311-1 | N/5cm N/5cm | 750-600 | -+ 25% +- 25% |

| Elongation at break | EN12311-1 | % % | 40-42 | -+ 25% +- 25% |

| Tear Resistance Long Nail – Shank) | EN12310-1 | N N | 150-200 | -+ 25% +- 25% |

| Tensile-tear Resistance Long Wide | ASTM-5147 | N N | 550-450 | -+ 25% +- 25% |

| Joint tensile strength Long Wide | EN 12317-1 | N/5cm N/5cm | 650-500 | -+ 25% +- 25% |

| Dimensional stability Long Wide | EN 1107-1 | % % | 0.5-0.5 | |

| Water absorptoin Long Wide | ASTM D -5147 | % % | 1% max | |

| Static puncture resistance | EN 12730:2001 | 20 kg | ||

| Dynamic puncture resistance | EN12691 | – | 1750 mm | |

| Water impermeability at 100 K pa | EN 1928:2000 | – | Abolutely impermeable | |

| Impermeability to water vapor | EN 1913 | u | 80.000 | |

| Ageing due to U.V. radiation | EN 1269 | – | Pass | |

| Resistance to thermal ageing | EN 1296 | – | No signs of deterioration after the test | |

| Adhesion to concrete | EN 13596 | N/cm2 | 40 | |

| Average Granule loss for Mineral Slated Finish | ASMT D-4977 | gm/m2 | Lass than 200 | |

Storage:

• BITUMODE membranes should be stored vertically in well covered and ventilated place not subject to direct sunlight.

APPLICATION INSTRUCTIONS :

• BITUMODE membranes are installed by propane torch welding method, loose laid or fully bonded to the substrate depending on system requirements.

- While unloading from truck the rolls shall by no means allowed to fall or be thrown down from the truck.

- To avoid applying the membrane to corners with 90 ° angle, sand cement cant strip 5x5 cm should be executed at horizontal – vertical intersections, Surface to be waterproofed should be clean, dry, free from dust and smooth, in case of irregular surface a sand cement screed is recommended

- Before laying BITUMODE membranes, surface should be primed with cold applied bituminous primer (NIROL – S) or (NIROL – W).Membrane is unrolled and placed in aligned position.

- Each roll should overlap the next by 10cm side laps and 15cm staggered end laps.

- Then, membrane should be re-rolled about half of its length without changing its orientation .

- Using a propane gas torch the membrane is un-rolled again slowly while applying the flame to the entire exposed lower face (For fully bonded system) – until the plastic cover film burns off and the bituminous mass starts melting, thus creating a heat weld between the membrane and the substrate :

- Then, torching of the seams takes place by heating the contact line at side and end laps by torch from above, pressing the upper membrane on to the lower one using a trowel, the torch has to be carefully used avoiding to keep the flame on the same point for too long

- For sloping roofs start laying the membrane from the lower edge with longitudinal direction of rolls perpendicular to slope direction, side lap of next roll to be placed above the first one, etc…

For detailed application procedures please refer to BITUMODE MANUAL GUIDE, where you can find construction detail drawings

PHONE

++(218)912145019

++(218)922145019

Email Address

info@anakhil.com

Address

ZLITEN – Near Al’iithad Cement Factory

Modern products

Bitumode Delta -P

Erock products

Rock wool

Glass wool

Contact times with us ..

Days : Saturday – Thursday

Time : 7:00 AM – 7:00 PM